|

|

|

|

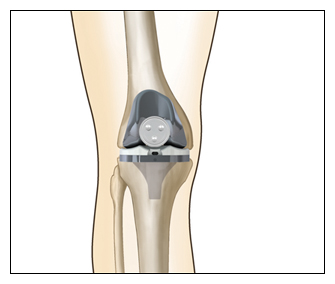

| Optetrak LOGIC® Knee System It is widely recognized that quality design and materials contribute to longevity and function when it comes to total joint implants. The design behind Optetrak began with a concept developed at the Hospital for Special Surgery in New York, one of the world’s leading orthopaedic research and treatment institutions. The patented design features and proprietary materials contribute to Optetrak’s overall longevity and excellent clinical performance, including 98 percent good to excellent results for up to 15 years. SOME OF THE SYSTEM’S UNIQUE

FEATURES INCLUDE: DESIGN One part of a knee system that is subject to wear is the place where the femoral and tibial components meet. When weight is placed unevenly, as often happens with normal activities of daily living, a high level of pressure may be exerted on the edge of the joint. This can lead to pain and discomfort. The unique shape of Optetrak Logic’s femoral and tibial components distributes weight and pressure more evenly across the area where the components meet, even when weight is concentrated on one side of the knee. Another key factor in the way a knee implant performs is the way the knee cap (patella) moves when you bend your knee. From the earliest knee designs, surgeons have struggled to recreate the correct patella tracking and limb alignment to ensure you have a comfortable, natural feel and function. Optetrak knee systems feature a wide femoral groove that allows the patient’s kneecap to track naturally (to either the inside or the outside) during normal bending and straightening of the leg. This is different than some competitive designs, which force the knee cap to track along a specific path that can cause pain or stress on the surrounding ligaments and muscles. MATERIALS Another important element of a knee implant

is the polyethylene or plastic that fits into the tibial tray and slides

against the femoral component. Variations in the way the plastic is

made, packaged, and sterilized can have a significant impact on the

long-term viability of the plastic itself.

|

Conditions & Treatments • ARTHRITIS OF THE KNEE AND HIP • TOTAL

KNEE REPLACEMENT • TOTAL

HIP REPLACEMENT

|